Strong Grip - Mechanism

- Mohamed Sami

- Nov 14, 2021

- 2 min read

The mechanical gripping is very useful to hold and lift heavy objects, usually the gripper uses as a end effector of mechanical lifting equipment.

The most important tip is how to lock the object avoiding slipping during lifting operation, it might be cause a fatal accident because of an heavy dropped object.

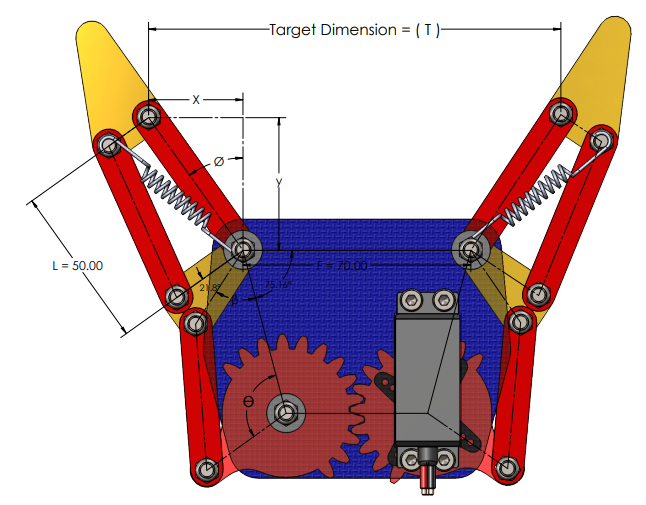

Gripper Mechanism

This mechanism divided by 2 parts [ Driving Mechanism - Finger Mechanism ], the two part of mechanism based on 4-bars linkage mechanism.

The mainly objective of the gripper mechanism is to grip and hold the cylindrical objects avoiding slipping or loosing the object which is caused a fatal accident.

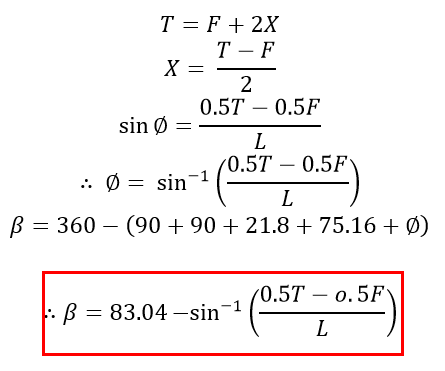

The main equation to control the mechanism considers (Target dimension - T) is an input and (Theta angle - Ѳ) is the output of equation, So the dimensions of object is the input to get a proper angle theta of mechanism.

Driving Mechanism

Basically, it is a 4-bars linkage mechanism that has been driven by 2 Spur gears to make sure the movement transfers from the motor to the 2 fingers at the same time.

The main objective of the next equation is to find Theta-Ѳ as a function of Beta-β

Finger Mechanism

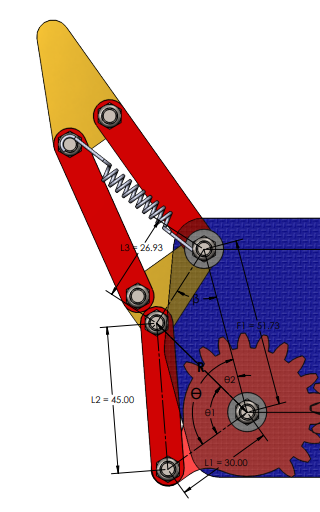

Based on 4-bars linkage mechanism supported by spring in diagonal line.

When the finger "L" reach the target distance and contacted with the object, the finger mechanism start operating to hold the object more avoiding slipping.

At this point the motor driving still working and the spring start to extend changing the angle "λ".

At the end when the gripper start to disengage with the object, the motor drive the linkage back to retrieve the spring to its normal distance first and then all the finger mechanism opened to release the object.

Comments